Sistemas de gestión de relaves

El procesamiento y almacenamiento de relaves mineros es un tema ambiental clave para los proyectos mineros en todo el mundo. Utilizando su experiencia en tecnologías de manejo de relaves, Westpro ofrece sistemas llave en mano que permiten reducir o eliminar las costosas presas de relaves.

Estos sistemas utilizan combinaciones de la línea de equipos de filtrado de la empresa, para reducir el volumen de lodo de relave producido por la planta. Un beneficio adicional es la recuperación de agua para su reutilización en el proceso, o en otro lugar de la planta.

Westpro can proposed three different solutions based on the project requirements.

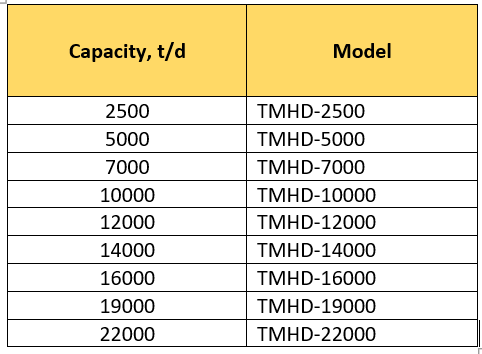

SOLUTION #1: TAILINGS MANAGEMENT HIGH DENSITY DISCHARGE

This cost-efficient and convenient tailing management solution for mines able to discharge their thickened tailings into tailings impoundment areas. This approach maximizes immediate water recovery while still utilizing a pond for final water recovery and solids storage. The Westpro Machinery High Density Underflow thickener (HDU) is capable of dewatering up to 22000 t/d per unit and delivering underflow with solid percentage up to 75%.

Multiple lines can be used if the capacity is greater than 22000 t/d.

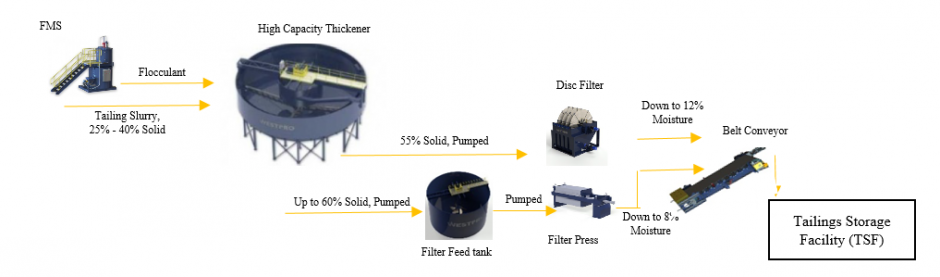

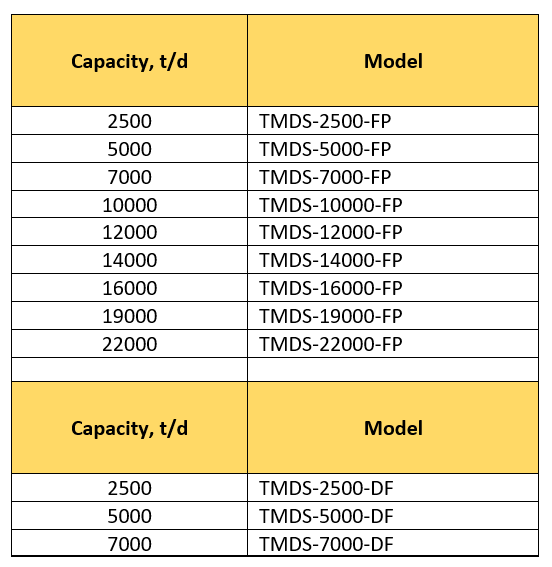

SOLUTION #2: TAILINGS MANAGEMENT DRY STACKING

For dry stacked tailings a high capacity thickener plus a disc filter can be used up to 7000 t/d. The capacity will increase up to 22000 t/d by replacing the disc filters with filter presses.

Multiple lines can be used if the capacity is greater than 22000 t/d.

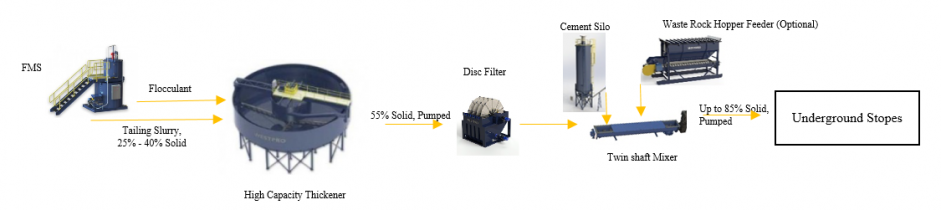

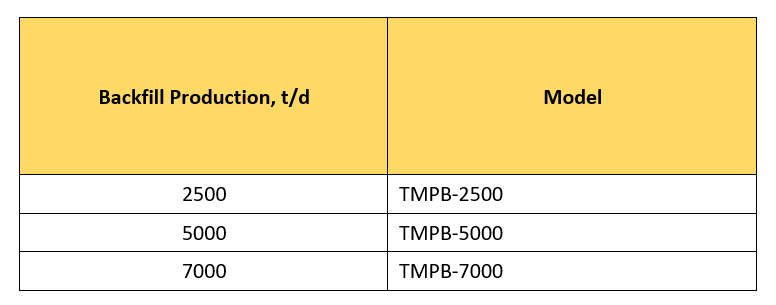

SOLUTION #3: TAILINGS MANAGEMENT PASTE BACKFILL

Cemented paste backfill technology has become an important component of underground mining operations. It provides a safe work environment by backfilling the underground stopes and offers an effective means of mine waste disposal. Westpro Machinery’s solution is a combination of a High Capacity Thickener and a Backfill plant to discharge tailings and backfill to underground stopes. Westpro Paste Backfill plant is able to dewater 7000 t/d and produce paste backfills up to 85% solids. Solution # 3 would be used with either Solution # 1 or Solution # 2 when backfill process is needed to be momentarily or permanently shut down.

Multiple lines can be used if the capacity is greater than 7000 t/d.

EQUIPO COMÚNMENTE UTILIZADO EN Sistemas de gestión de relaves

Agitadores

Diseñados a la medida para cada aplicación, los Agitadores de Westpro proporcionan un rendimiento confiable y son energéticamente eficientes en aplicaciones demandantes de mezclado de pulpa.

Clarificadores

Los Clarificadores de Westpro han demostrado el desempeño del tratamiento de aguas residuales en aplicaciones municipales e industriales.

Filtros de disco

Los filtros de disco de Westpro son máquinas versátiles con aplicaciones en una variedad de industrias.

Filtros prensa

Los Filtros Prensa de Westpro son adecuados para una amplia variedad de industrias, y están completamente personalizados según los requisitos del cliente

Sistemas de preparación y dosificación de floculantes

Westpro diseña y fabrica sistemas modulares llave en mano de Preparación y Dosificación de Floculantes.

LIME SLAKING AND LIME MIXING SYSTEMS

Completamente personalizable en términos de suministro de equipos, distribución, y condiciones de la planta.

Sistemas de preparación y dosificación de reactivos

Westpro diseña y fabrica sistemas completos de preparación y dosificación de reactivos.

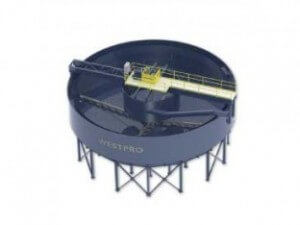

Espesadores

Equipados con motores hidráulicos de última generación y rastrillos de bajo arrastre y alta capacidad.