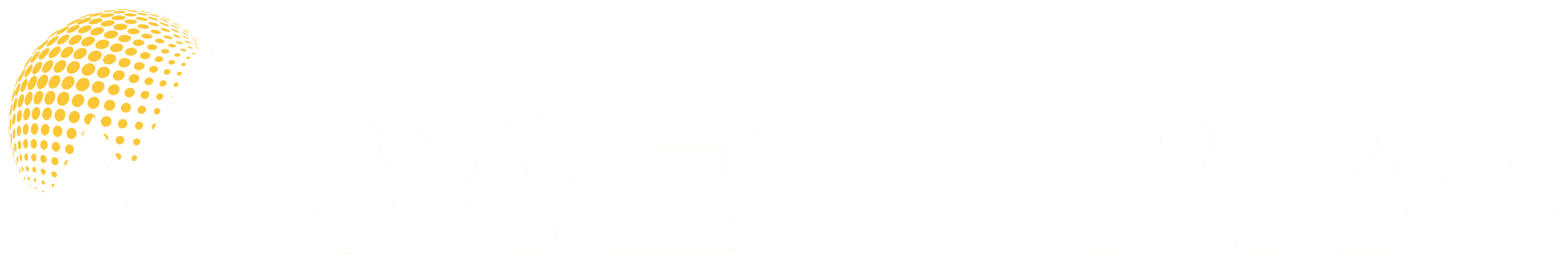

Flotation Machines (Conventional)

Utilising the company’s wealth of experience in the mineral processing industry, Westpro’s flotation machines are designed for efficient and optimal performance in all mineral flotation applications (gold, base metals, potash, lithium and more).

ADVANTAGES

- Cell capacities ranging from 0.01m ( 0.5ft³ ) to 14m³ ( 500ft³ )

- Available in custom layout configurations to meet the required flotation residence time

- Variety of replaceable wear components available.

APPLICATIONS

- Mineral Separation

- Industrial Minerals

Download our brochure for more details including advantages and applications.

Click the gold circles below for an in-depth look at some of our key features!

Carbon Steel Tank

The Heavy-Duty Carbon Steel Tank comes with replaceable wear liners to deliver exceptional resistance to wear, abrasion, and impact.

Optional:

- Ceramic Tile Lining offers unmatched durability for extreme operating conditions.

Polypropylene Tank

OPTIONAL:

- The Polypropylene Tank option provides outstanding chemical resistance - ideal for high-pH slurry or flotation circuits using aggressive reagents such as frothers, collectors, and NaOH or H2SO4.

Precision-Design Froth Paddles

Westpro's Precision-Designed Froth Paddles are meticulously designed to gently guide froth toward the discharge lip, ensuring smooth flow and maximizing concentrate recovery through consistent, accurate, and uniform froth handling.

Overflow Launders

Optional:

- Single or Duel Overflow Launders are available for increased cell capacity and enhanced froth collection efficiency - supporting higher throughput and improved recovery.

Belt-Driven System

The Belt-Driven System offers efficient power transmission, reduced startup torque, and built-in shock absorption - providing the whole system with smooth operation and simplified maintenance routines to further reduce any downtime.

Drive Shafts & Standpipes

Robust Drive Shafts and Standpipes come available in your choice of Carbon Steel for increased abrasion-resistance or Corrosion-Resistant Stainless Steel for enhanced durability in chemically aggressive environments.

Urethane Wet Ends

Westpro's Urethane Wet Ends provide optimized air dispersion through the impeller (or rotor for those using Westpro's W19 flotation technology) for consistent bubble generation and ideal quiescent zones.

Dart Valves

Your choice of Standard Automatic or Manual Dart Valves maintain precise pulp levels, control inter-cell flow, and sand relief - to ensure stable operation and preventing any potential blockages.

Responsive Level Control System

The Responsive Level Control System maintains optimal operating conditions for your system - boosting recovery rates, stabilizing performance, and ensuring consistent product quality.

Automatic Air Flow Control

Optional:

- Westpro's Conventional Flotation Machine provide users with the option of Automatic Air Flow Control per each individual cell. This gives the systems even further successional process balancing.

| Model | Volume Per Cell (Cubic Feet) | Volume Per Cell (Cubic Meter) | Motor hp |

|---|---|---|---|

| FL0.2 | 0.2 | 0.006 | 0.17 |

| FL0.5 | 0.5 | 0.014 | 0.5 |

| FL3 | 3 | 0.085 | 1.5 |

| FL12 | 12 | 0.4 | 3 |

| FL24 | 24 | 0.68 | 5 |

| FL50 | 50 | 1.41 | 7.5 | FL100 | 100 | 2.83 | 15 | FL200 | 200 | 5.1 | 20 | FL300 | 300 | 8.9 | 30 | FL500 | 500 | 14.16 | 50 |

Complementary Equipment

Filter Presses

Westpro’s filter presses are suitable for applications in wide variety of industries and are fully customized to the requirements of each customer.

Flotation Tank Cells

Developed through an extensive R&D process, Westpro’s Flotation Tank Cells deliver industry- leading flotation performance in a variety of applications.

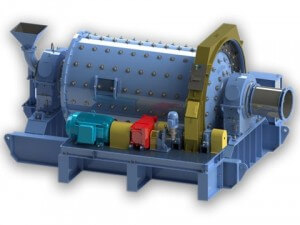

Grinding Mills

Westpro’s heavy duty grinding mills are designed for durability and excellent grinding performance in mining applications.

Pilot and Laboratory Equipment

In addition to its line of production machinery, Westpro manufactures a comprehensive range of pilot- and laboratory- scale equipment.