Grinding Mills

Westpro’s heavy duty grinding mills are designed for durability and excellent grinding performance in mining applications.

ADVANTAGES

- Sizes up to 4.9m (16tf) diameter and 4500hp (3356KW)

- Available with rubber, steel or ceramic liners

APPLICATIONS

- Size reduction of various materials

- Feed sizes of 1/2″ to product sizes of 325 mesh

PROMPT DELIVERIES

HEAVY-DUTY CONSTRUCTION

LOW MAINTENANCE

CUSTOM FITTING MODULAR FRAME

ROD MILL

As the first step in the grinding process, Westpro’s durable and reliable Rod Mills provide excellent primary grinding of rocks and minerals.

ADVANTAGES

- Coarse grinding of up to 1in feed

- Ideal for primary grinding and open circuit grinding

- Longer life for grinding media.

- Most economical option for primary grinding

- Long lasting cast wear liners.

Sizes

| Models | Dia. x Length | HP | Models | Dia. x Length | HP | Models | Dia. x Length | HP |

|---|---|---|---|---|---|---|---|---|

| RM1636″ | 16″ x 36″ | 4 | RM710 | 7′ x 10′ | 200 | RM1020 | 10′ x 20′ | 900 |

| RM24 | 2′ x 4′ | 10 | RM712 | 7′ x 12′ | 250 | RM1116 | 11′ x 16′ | 900 |

| RM36 | 3′ x 6′ | 15 | RM714 | 7′ x 14′ | 300 | RM1118 | 11′ x 18′ | 1000 |

| RM48 | 4′ x 8′ | 50 | RM816 | 8′ x 16′ | 450 | RM1120 | 11′ x 20′ | 1100 |

| RM58 | 5′ x 8′ | 75 | RM914 | 9′ x 14′ | 500 | RM1220 | 12′ x 20′ | 1500 |

| RM510 | 5′ x 10′ | 100 | RM916 | 9′ x 16′ | 600 | RM1224 | 12′ x 24′ | 1250 |

| RM68 | 6′ x 8′ | 125 | RM918 | 9′ x 18′ | 600 | RM1318 | 13′ x 18′ | 1500 |

| RM610 | 6′ x 10′ | 150 | RM1014 | 10′ x 14′ | 600 | RM1322 | 13′ x 22′ | 2000 |

| RM612 | 6′ x 12′ | 200 | RM1018 | 10′ x 18′ | 800 | RM1422 | 14′ x 22′ | 2500 |

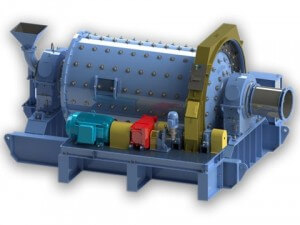

BALL MILL

Westpro’s Ball Mills ensure fine grinding of minerals and ore. Our Ball Mills are engineered to provide the most efficient solution for fine finishing.

ADVANTAGES

- Liners are less expensive than Rod Mill steel liners

- Ideal for fine grinding applications

- Easy grinding media handling

SIZES

| Models | Dia. x Length | HP | Models | Dia. x Length | HP | Models | Dia. x Length | HP | Models | Dia. x Length | HP |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BM1616″ | 16″ x 16″ | 2 | BM58 | 5′ x 8′ | 100 | BM914 | 9′ x 14′ | 600 | BM1220 | 12′ x 20′ | 1750 |

| BM1624″ | 16″ x 24″ | 2 | BM510 | 5′ x 10 | 125 | BM916 | 9′ x 16′ | 700 | BM1222 | 12′ x 22′ | 2000 |

| BM1632″ | 16″ x 32″ | 3 | BM66 | 6′ x 6′ | 100 | BM918 | 9′ x 18′ | 800 | BM1224 | 12′ x 24′ | 2000 |

| BM1648″ | 16″ x 48″ | 5 | BM68 | 6′ x 8′ | 150 | BM1010 | 10′ x 10′ | 600 | BM1313 | 13′ x 13′ | 1250 |

| BM22 | 2′ x 2′ | 7.5 | BM610 | 6′ x 10′ | 200 | BM1012 | 10′ x 12′ | 700 | BM1315 | 13′ x 15′ | 1500 |

| BM23 | 2′ x 3′ | 7.5 | BM612 | 6′ x 12′ | 200 | BM1014 | 10′ x 14′ | 800 | BM1316 | 13′ x 16′ | 1750 |

| BM24 | 2′ x 4′ | 10 | BM77 | 7 x 7′ | 200 | BM1016 | 10′ x 16′ | 900 | BM1319 | 13′ x 19′ | 2000 |

| BM33 | 3′ x 3′ | 10 | BM710 | 7′ x 10′ | 250 | BM1018 | 10′ x 18′ | 1000 | BM1322 | 13′ x 22′ | 2250 |

| BM34 | 3′ x 4′ | 15 | BM712 | 7′ x 12′ | 300 | BM1020 | 10′ x 20′ | 1250 | BM1326 | 13′ x 26′ | 2500 |

| BM35 | 3′ x 5′ | 20 | BM714 | 7′ x 14′ | 350 | BM1111 | 11′ x 11′ | 800 | BM1414 | 14′ x 14′ | 1750 |

| BM36 | 3′ x 6′ | 25 | BM88 | 8′ x 8′ | 300 | BM1113 | 11′ x 13′ | 900 | BM1416 | 14′ x 16′ | 2000 |

| BM44 | 4′ x 4′ | 25 | BM810 | 8′ x 10 | 350 | BM1116 | 11′ x 16′ | 1250 | BM1420 | 14′ x 20′ | 2500 |

| BM45 | 4′ x 5′ | 30 | BM812 | 8′ x 12′ | 400 | BM1120 | 11′ x 20′ | 1500 | BM1424 | 14′ x 24′ | 3000 |

| BM46 | 4′ x 6′ | 40 | BM814 | 8′ x 14′ | 450 | BM1122 | 11′ x 22′ | 1500 | BM1428 | 14′ x 28′ | 3500 |

| BM47 | 4′ x 7′ | 40 | BM816 | 8′ x 16′ | 500 | BM1212 | 12′ x 12′ | 1000 | BM1522 | 15′ x 22′ | 3000 |

| BM48 | 4′ x 8′ | 50 | BM99 | 9′ x 9′ | 400 | BM1214 | 12′ x 14′ | 1250 | BM1624 | 16′ x 24′ | 4000 |

| BM55 | 5′ x 5′ | 60 | BM910 | 9′ x 10′ | 450 | BM1216 | 12′ x 16′ | 1500 | |||

| BM56 | 5′ x 6′ | 75 | BM912 | 9′ x 12′ | 500 | BM1218 | 12′ x 18′ | 1500 |

BATCH BALL MILL

ADVANTAGES

- Ideal for low tonnage batch applications

- Compact and small foot print

- Economical solution for periodical fine grinding demands

- Long equipment life

- Low maintenance

SIZES

| Models | Dia. x Length | Models | Dia. x Length |

|---|---|---|---|

| BM22B | 2′ x 2′ | BM35B | 3′ x 5′ |

| BM24B | 2′ x 4′ | BM44B | 4′ x 4′ |

| BM33B | 3′ x 3′ | BM46B | 4′ x 6′ |

| AVAILABLE 16″ TO 8″ DIAMETER |

BUILT TO THRIVE IN THE TOUGHEST MINERAL PROCESSING ENVIRONMENTS

Complementary Equipment

Flotation Machines (Conventional)

Westpro’s flotation machines are designed for efficient and optimal performance in all mineral flotation applications (gold, base metals, potash etc.).

Flotation Tank Cells

Developed through an extensive R&D process, Westpro’s Flotation Tank Cells deliver industry- leading flotation performance in a variety of applications.

Portable Crushers

Westpro’s portable jaw and cone crusher units deliver self-contained crushing solutions for quarries, remote sites and construction projects.

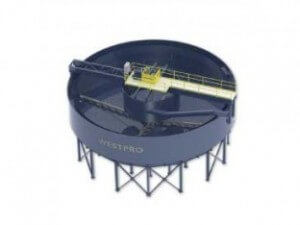

Thickeners

Equipped with new generation hydraulic drives and low drag, high capacity rakes, Westpro’s thickeners deliver superior solids settling performance.