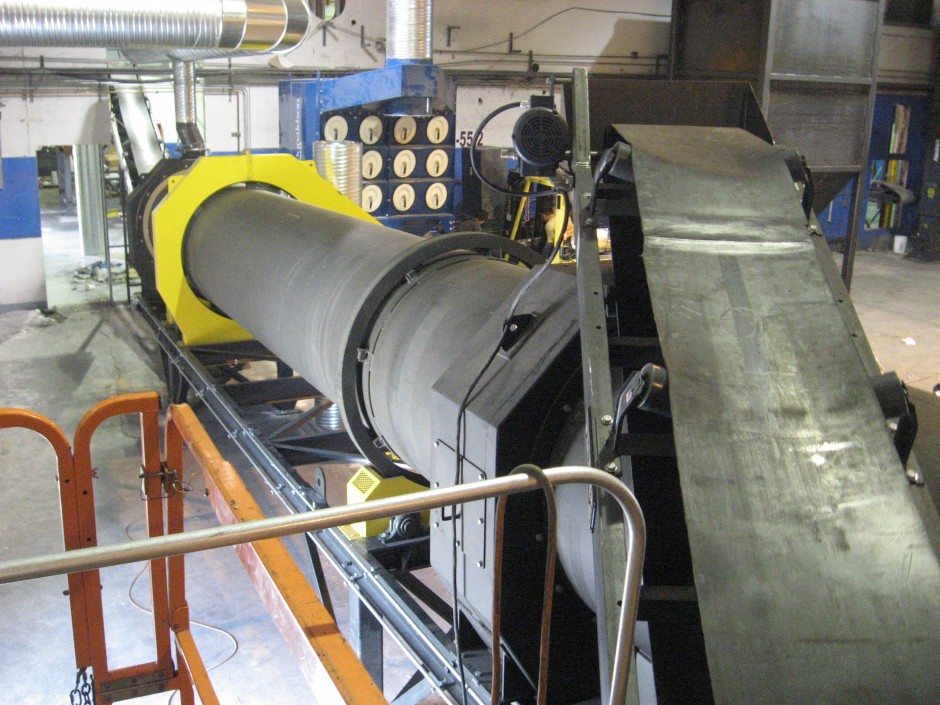

Rotary Dryers

Custom designed for each application, Westpro’s Rotary Dryers deliver efficient and cost-effective drying performance.

SPECIFICATIONS

- Dryer sizes range from 0.6m (2ft) diameter to 2.7m (9ft) diameter

- Designed for high temperature drying applications

- Specially forged riding rings and rollers ensure long-life and low maintenance operation

- Custom lifter configuration to optimize material drying

- Dryers can be mounted on concrete piers, portable frame or modular frame

- Available add-ons include refractory lined combustion chambers, burners and dust collection systems

- QUICK DELIVERIES

- SOLID CONSTRUCTION

- PROVEN DESIGN

APPLICATIONS

- Aggregate

- Soil Remediation

- Concentrate

- Industrial Minerals

- Many Other Drying Applications

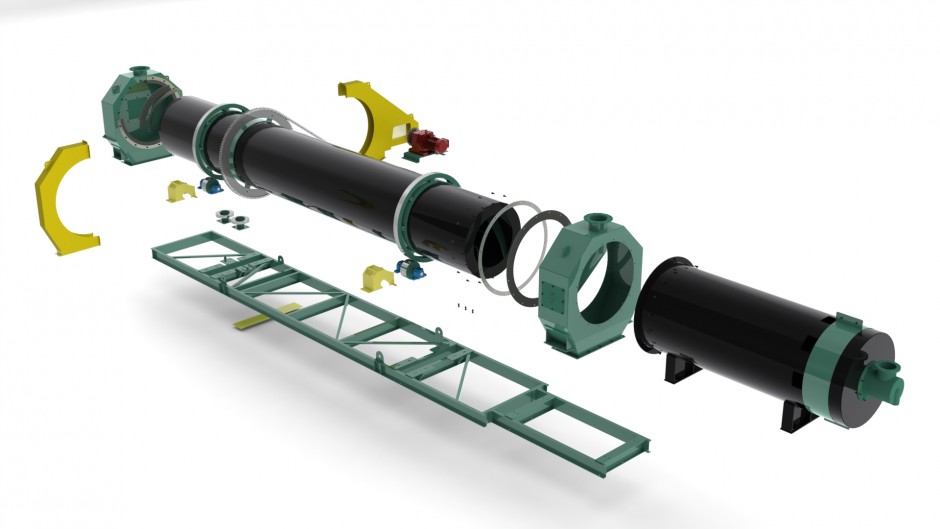

CHAIN DRIVE ROTARY DRYERS

ADVANTAGES

- Low maintenance

- Most economical option

- Rugged design

- Simple installation

DIRECT DRIVE ROTARY DRYERS

ADVANTAGES

- Low spare parts cost

- Low maintenance

- Riding ring is self aligning

- No open gearing or chain to lubricate and maintain

GEAR DRIVE ROTARY DRYERS

ADVANTAGES

- High tonnage application

- Positive drive engagement

- Long wear life on drive train and gearing

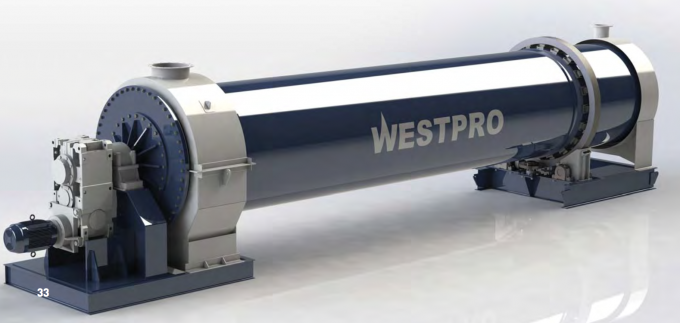

STANDARD SIZES*

| Model | Size (Diameter X Length) |

|---|---|

| RD215 | 2′ X 15′ |

| RD324 | 3′ X 24′ |

| RD428 | 4′ X 28′ |

| RD535 | 5′ X 35′ |

| RD635 | 6′ X 35′ |

| RD740 | 7′ X 40′ |

| RD965 | 9′ X 65′ |

*Other Sizes Available

Complementary Equipment

Disc Filters

Westpro’s disc filters are versatile machines with applications in a variety of industries.

Filter Presses

Westpro’s filter presses are suitable for applications in wide variety of industries and are fully customized to the requirements of each customer.

Flotation Machines (Conventional)

Westpro’s flotation machines are designed for efficient and optimal performance in all mineral flotation applications (gold, base metals, potash etc.).

Thickeners

Equipped with new generation hydraulic drives and low drag, high capacity rakes, Westpro’s thickeners deliver superior solids settling performance.