The Processor’s Playbook: Proven Ways to Optimize Your Lime Slaking Systems

Lime slaking Systems isn’t just another step in your industrial process. It can play a vital role in the overall productivity of your site. When operated to its full potential, the Lime Slaking System provides a highly necessary pH regulation and balance that keeps your process running at peak performance. But when done wrong, expect downtime, inefficiencies and skyrocketing operational costs… that’s why we’re here to help ensure you’ve got the proper tools to turn your Lime Slaking System into the powerhouse your process deserves!

Here are the best ways to optimize performance and get the most out of your Lime Slaking System:

Choose the Right Lime for Maximum Reactivity

Not all quicklime (CaO) is created equal. Variability in purity and particle size directly impacts your slaking efficiency, and using sub-quality lime can sometimes lead to grit build-up, incomplete reactions, and increased maintenance headaches.

Best Practices:

✅ Source high-purity quicklime with consistent CaO content from reputable suppliers. Request a Certificate of Analysis (COA) to verify quality, as the presence of other compounds can sometimes make a major difference

✅ Ensure optimal performance of your lime slaking system by testing lime quality regularly. Analyze particle size and reactivity to fine-tune your process and improve efficiency.

✅ Store quicklime in a dry, temperature-controlled environment to prevent premature hydration.

✅ Use a variable-speed lime feeder to adjust the addition rate based on reactivity tests.

✅ Pre-wet the lime feed before introduction to the slaker to improve reaction consistency, reduce dusting and caking, and promotes initial hydration.

Optimize the Water-to-Lime Ratio for a Perfect Slurry

The ideal water-to-lime ratio ensures complete hydration while preventing excessive heat generation. Too much water? You get a dilute and inconsistent slurry. Too little? You risk incomplete hydration and operational inefficiencies.

Best Practices:

✅ Use real-time monitoring to maintain your optimal % solids concentration in your slurry.

✅ Adjust water quality. Hard water accelerates scaling, while soft water optimizes hydration.

✅ Design piping with accurate velocity – preventing blockages and minimizing excessive wear.

✅ Implement routine flushing programs to keep pipelines clear.

✅ Consider periodic acid washes to remove buildup (e.g., citric or hydrochloric acid).

Control Temperature for Peak Performance

Lime slaking is an exothermic reaction, meaning it can generate a lot of heat! Too much heat causes flash slaking and grit formation, while low temperatures slow down hydration, leading to poor slurry quality.

Best Practices:

✅ Use temperature sensors and automation to adjust water feed dynamically and maintain an ideal slaking environment.

✅ Avoid excessive lime feed rates. Too much material leads to incomplete reactions and high temperatures.

✅ Ensure proper venting to release excess steam and prevent overheating.

✅ Invest in high-efficiency slakers with adjustable retention time to fine-tune reaction conditions.

Prevent Equipment Wear and Scaling Issues

Lime slurry and associated grits are highly abrasive, and without the right precautions, your equipment will wear out fast. Scaling and clogging can also be a battle that will reduce efficiency and increase maintenance downtime.

Best Practices:

✅ Use abrasion-resistant materials like rubber-lined pipes, and carbon-steel components.

✅ Install sacrificial wear plates in high-impact areas.

✅ Maintain proper slurry density. Too thick accelerates wear, while too thin reduces efficiency.

✅ Regularly inspect and replace worn components, including impellers, seals, and piping elbows.

Automate for Precision and Consistency

An optimized lime slaking process relies on precise control over feed rates, water ratios, and mixing conditions. Poor automation leads to under- or over-slaking, inconsistent slurry quality, and increased grit formation.

Best Practices:

✅ Implement PLC-based automation to regulate lime dosing, water flow, reaction temperature and mixing time. This could also be used for data logging for process analysis and optimization over time.

✅ Install real-time pH monitoring in downstream applications to improve control of both the downstream process and consumption rate.

✅ Regularly calibrate flow meters and level sensors to maintain accuracy.

✅ Monitor slurry viscosity and adjust water feed for optimal performance.

A well-run lime slaking process provides efficient pH balance, reduced plant maintenance, and high-quality slurry for your process. By choosing high-quality lime, optimizing your water-to-lime ratio, and maintaining precise temperature control, while also preventing equipment wear and investing in automation, you can significantly enhance your lime slaking system’s performance and profitability.

Start implementing these best practices today, and watch your lime slaking system transform into a powerhouse of efficiency and cost savings!

BONUS!

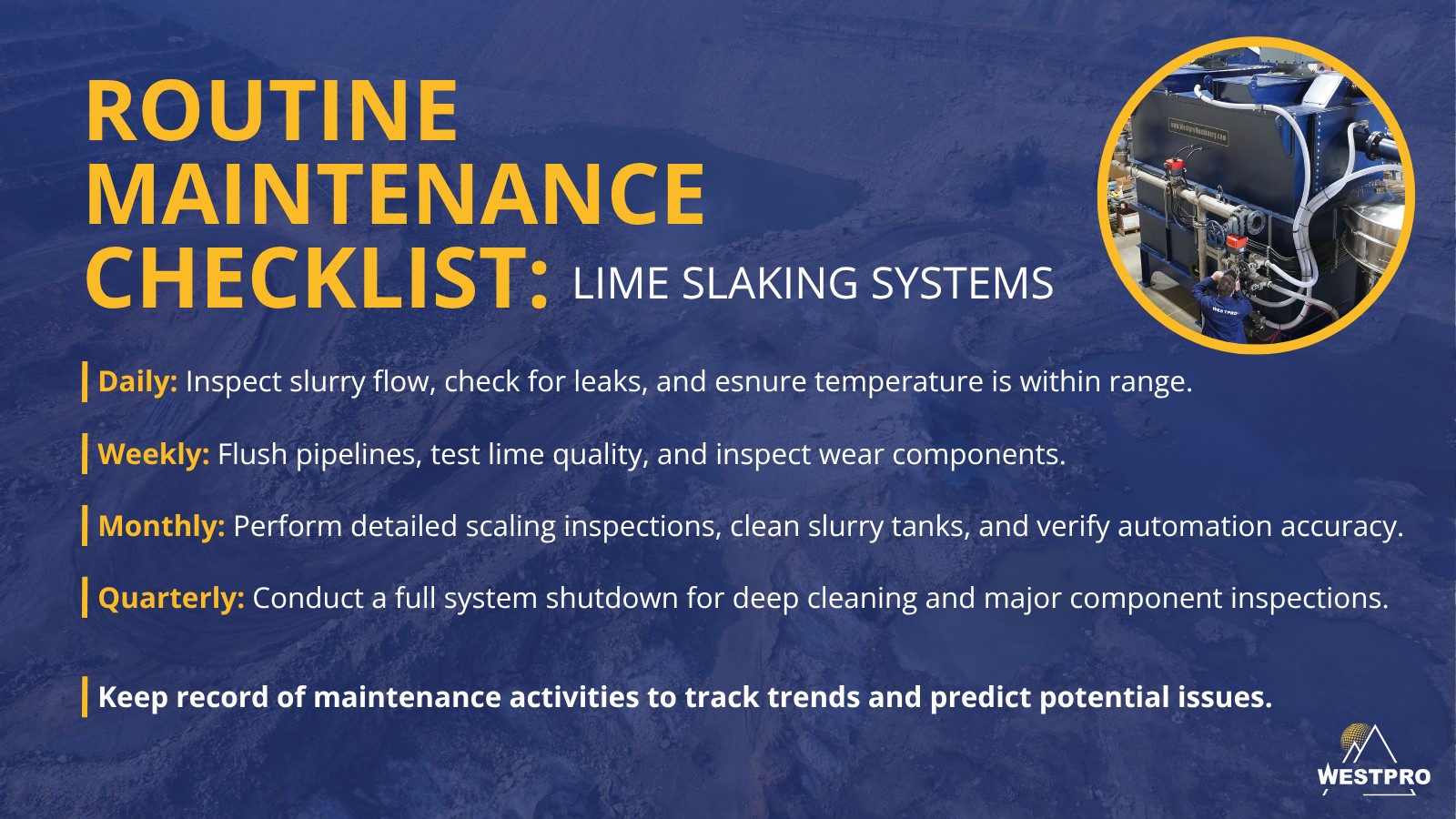

Stay on Top of Your Preventative Maintenance

Keep Your System Running like a Dream!

Even the best lime slaking systems require routine maintenance to avoid costly downtime. Stick to this checklist to keep your operation in peak condition:

Westpro Wants to Take Your Lime Slaking Project to the Next Level!

Choose a Lime Slaking Solution that Aligns with Your Goals

Westpro Machinery’s Lime Slaking Systems are engineered to tackle the common challenges in lime slaking operations, offering technical features that enhance efficiency and reliability:

High-Capacity Processing

Designed to handle quicklime throughput capacities of up to 30 tons per hour, accommodating large-scale operations.

Automated PLC-Controlled Operation

Incorporates programmable logic controller (PLC) systems to automate the slaking process, ensuring consistent control over feed rates, water ratios, temperatures, and mixing time, reducing human error and enhancing safety.

Comprehensive Turnkey Solutions

Provides complete systems from lime storage all the way to milk-of-lime dosing pumps. Our systems are equipped with pumps, piping, instrumentation, and control systems, facilitating seamless integration into existing operations and minimizing setup time.

Modular Design

Features a modular construction that allows for customization based on specific site conditions and operational requirements, ensuring optimal performance across various applications.

Integrated Dust Control System

Equipped with dust-controlled bag breaking enclosures, filtered silo exhausts and integral dust scrubber systems for the slaker process. Also, contributing to a safer and cleaner operating environment.

Robust Construction

Utilizes heavy-duty construction and materials designed to withstand the abrasive nature of lime slurry, extending equipment lifespan and reducing maintenance costs.

Grit Removal System

Incorporates vibrating screens and classifiers to effectively separate unreacted grit from the slurry, ensuring high-quality output and preventing equipment clogging.

Configurable Feed Handling Modules

Offers various feed handling modules, including silos engineered for quicklime or hydrated lime and bag breakers with integral hoisting mechanisms, tailored to specific storage and handling needs.

Get a Head Start on Slaking Smarter – Contact Us Today!

So, what are you waiting for? Contact us today and let our mineral processing experts size/design the perfect Lime Slaking System for your project!