Modular Lime Slaking Systems

Westpro Machinery Inc. offers a comprehensive design of lime slaking and mixing systems. Our complete package is a collaborative effort based on the data and specifications provided by our clients in conjunction with the years of experience of our Process and Design Engineers. Westpro has Quality Assurance systems encompassing all phases of design, development, engineering, production, installation, commissioning, and servicing.

Fully customizable based on equipment supply, layout, and site conditions, Westpro’s Lime Slaking Systems offer an optimized, turnkey slaking solution for your project.

BENEFITS

- On-demand system

- Quick turn around

- Shippable worldwide

- Supplied complete with pumps, piping, and instrumentation

- Proven safety and efficiency

- Dust controlled bag breaking enclosure

- Wide range of capacities up to 150 metric tonnes per hour.

- PLC-controlled automated process.

- Complete turnkey system

- Modular design and construction

CAPACITIES UP TO 150 TONS PER HOUR

PLC CONTROLLED AUTOMATED PROCESS

COMPLETE TURNKEY SYSTEM

Lime Slaking Systems Applications

Environmental

- Freshwater and Wastewater treatment

- Sewage Treatment

- Mining and Mineral Processing

- Dewatering of mineral concentrate slurries.

- Froth flotation of valuable minerals as a depressant and pH modifier

- Acid Mine Drainage Treatment

- Tailings Handling and Neutralization

- Cyanide lixiviants pH control in mineral leaching processes

- Fines agglomeration promoter in acid effluent and spent heaps treatment.

- Industrial

- Paper Manufacturing

- Sugar processing

- Plastics manufacturing

Lime Slaking System: Silo with 240 metric

tonnes storage capacity

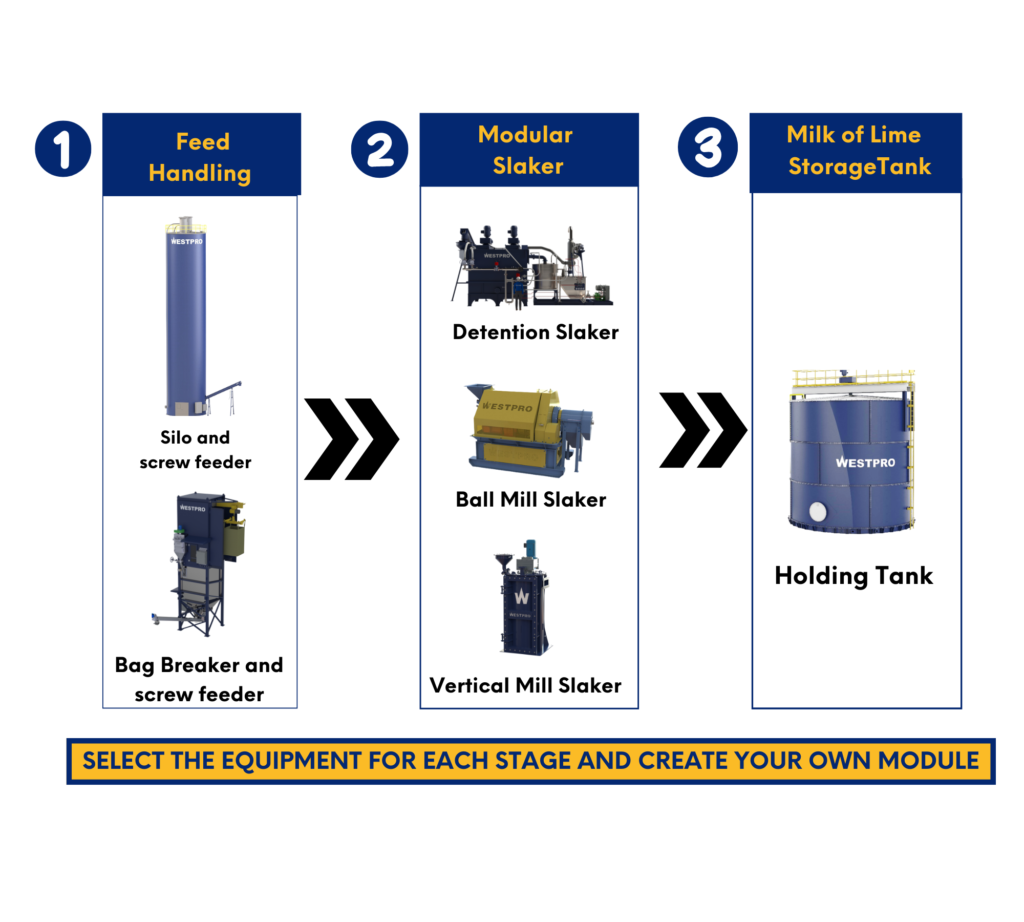

Modular Lime Slaking System

Tailored Lime Slaking Solutions for Your Unique Needs

At Westpro, we recognize that every client has specific requirements. That’s why we’ve designed a Modular Lime Slaking System that empowers you to customize your lime slaking process based on your unique needs.

tonnes storage capacity

Leading-Edge Technology

I. Feed Handling Module

Silo

- It can be welded or bolted with safety as the primary criteria.

- Engineered for quicklime or hydrated lime.

- Designed for operator-friendly lime transfer from delivery transport.

- The integral dust scrubber system defines Westpro’s commitment to environmental protection.

- Capacities can be tailor-made for each site-specific application.

BENEFITS

- Allows flexibility in inventory capabilities.

- Requires less ground space.

- Pneumatic transfer offers convenient and hassle-free handling.

- Low CAPEX cost.

Bag Breaker

- Highly efficient bulk bag handling technology.

- Engineered with an integral and safe hoisting mechanism.

- Designed with Westpro’s environmental commitment to dust handling in mind.

- Suitable for space-limited applications.

BENEFITS

- Eliminates manual bag opening and handling operations.

- Suited for the safe unloading and handling of lime in bulk bags.

- Environmentally friendly with an integral dust handling system.

- It can be fitted even in the most demanding space in the plant.

II. Modular Slaker Module

Detention Slaker

Westpro’s Detention Slakers have been engineered to handle pebble as well as fine lime. Our PLC based control system provides a safe and trouble free operation while functioning at peak productivity.

BENEFITS

- • High reactivity product

- • Available in standard sizes up to 150 metric tonnes per hour.

- • Vibrating screen provides separation of reaming grit and impurities

- • Integral control system monitor and automatically adjusts operation parameters for maximum safety and productivity

- • Low initial capital investment

Ball Mill Slaker

Westpro’s Ball Mill lime slaking design provides excellent slaking of lime while discharging no grit. Our system ensures the finest particle size by recycling coarse particles for further grinding.

BENEFITS

- Safe, simple, and operations- and maintenance-friendly operation

- The integral control system monitors and automatically adjusts operation parameters for maximum safety and productivity.

- Ensures optimum lime reactivity

- No practical upper limit for capacity

- Grit-free discharge, eliminating additional material handling

- Recycles coarse particles to the mill for further grinding

- Designed as a free-standing unit not requiring a foundation

- Operates either with fresh or reclaimed process water.

- Useful for water high in sulfates or sulfites

Vertical Mill Slaker

No matter the quality of lime or water, Westpro’s Vertical Mill Slaker provides excellent slaking of lime. Additionally, our Vertical Mill’s high efficiency will ensure the complete use of the quicklime regardless of the water or lime quality, resulting in a more cost-effective solution – ultimately saving money for the user.

BENEFITS

- Energy efficient

- Small environmental footprint

- High Capacity

- Can accept high sulfite/sulfate water

- Can accept low-quality lime

- Recycles coarse particles to the mill for further grinding

- Eliminates the need for grit disposal

- Fully automated system

- Excellent process control with temperature transmitter in slaking zone

- No exposed moving parts, making operation safer

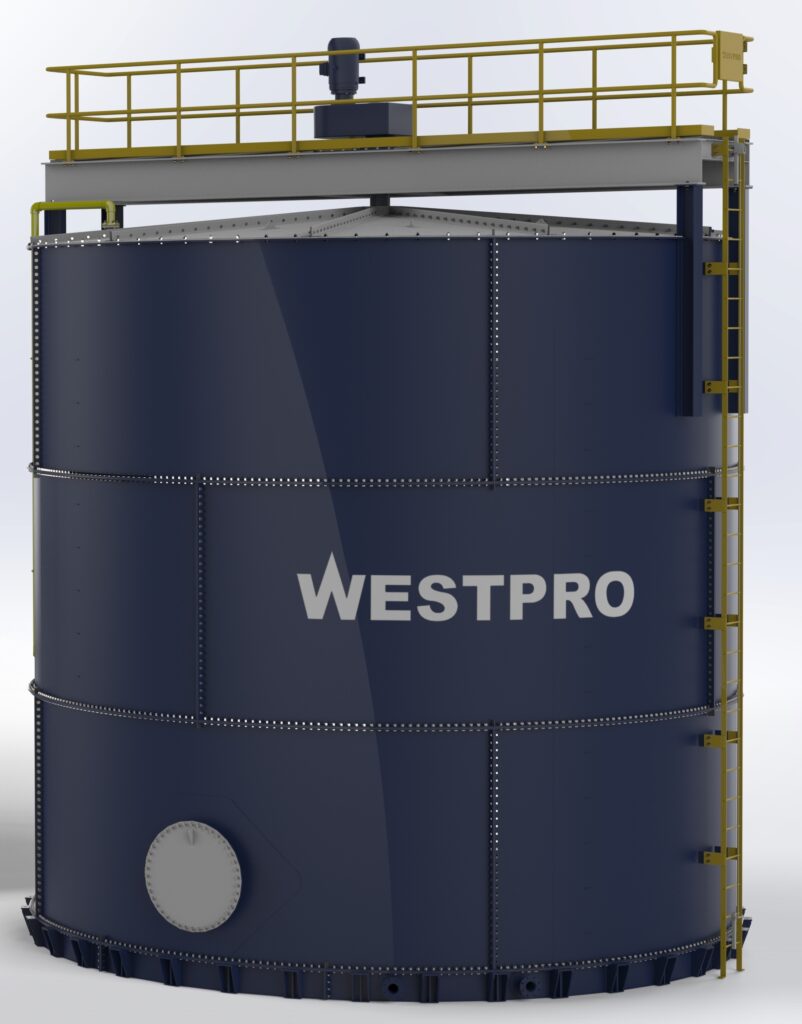

III. Milk of Lime Storage

Westpro’s lime storage tanks are engineered with the customer’s safety, operational productivity, and flexibility as the overriding premise.

BENEFITS

- It can be sized according to the site-specific requirement.

- Engineered for easy hook-up of dosing and recirculation lines.

- Rigid construction.

- Designed for ease of maintenance and clean up.

- Comes with automatic level systems for operations-friendly monitoring and control.

DURABLE DESIGN PROVIDES OVER 20 YEARS OF OPERATIONAL USE

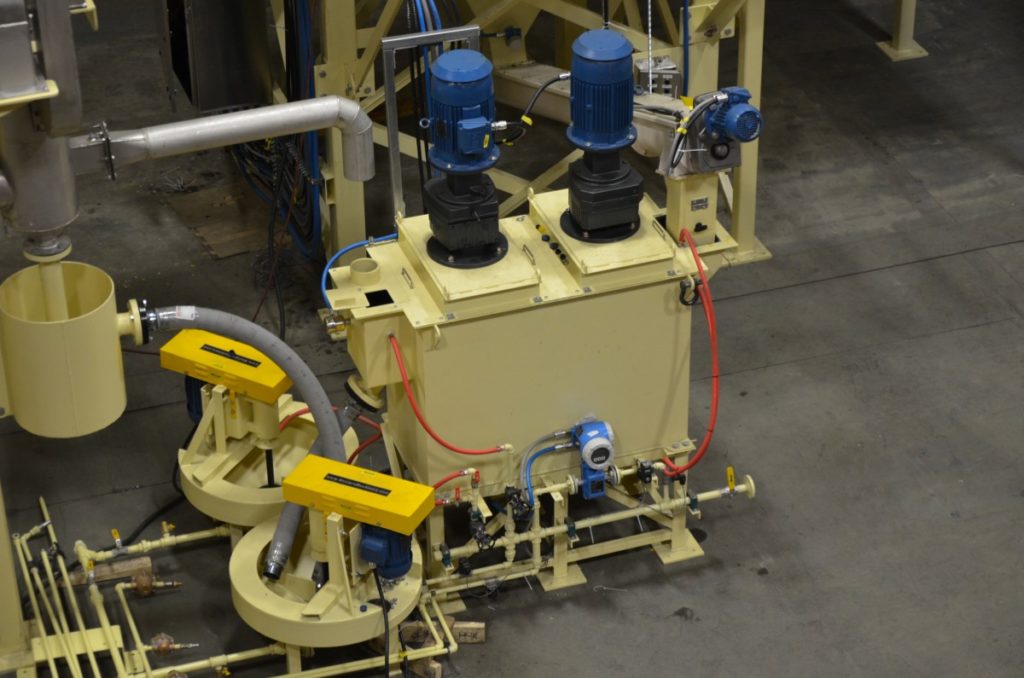

Lime Mixing System

Westpro also designs and supplies hydrated lime mixing systems suited to every client’s specific needs.

BENEFITS

- Fully automated.

- Wide range of capacities.

- Engineered for safety, operability, and productivity.

- Fully-contained system mitigating the risks of environmental spills.

- Comes with automatic level systems for operations-friendly monitoring and control.

Complementary Equipment

Clarifiers

Westpro’s Clarifiers have delivered proven wastewater treatment performance in both municipal and industrial applications.

Flocculant Preparation & Dosing Systems

Westpro’s designs and manufactures turnkey modular Flocculant Preparation & Dosing Systems.

Flotation Machines (Conventional)

Westpro’s flotation machines are designed for efficient and optimal performance in all mineral flotation applications (gold, base metals, potash etc.).

Reagent Preparation & Dosing Systems

Westpro designs and manufactures turnkey modular Reagent Preparation & Dosing systems with compact footprints.