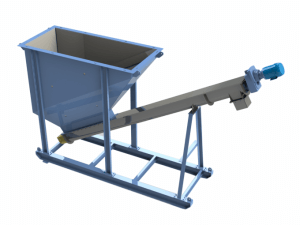

Hopper Feeders

Available as stationary, modular and portable units, Westpro’s heavy duty Hopper Feeders are suitable for any scale of mining or aggregate project.

- Capacities of up to 100 tons

- Top dimensions customizable to client’s loader bucket

- Abrasion resistant lining available

- Stationary or hydraulically actuated tilting grizzly available

- Designed to promote material flow through hopper and minimize hold-up

- Belt or screw feeder options available

- VFD’s available for feeder drives to control material feed rate

- Option for magnetic separation capabilities

- Portable units include complete road-worthy chassis assembly and hydraulic power units

ADAPTABLE TO ANY TEMPORARY SOLID STORAGE APPLICATION

ADVANTAGES

- Removable and Adjustable Grizzly Bars

- Proven Long Life Grizzly Bars

Download our brochure for more details.

APPLICATIONS

- Surge Hopper

- Uniform Feeding System

SPECIALLY DEVELOPED HOPPER CONFIGURATION ALLOWS CLEAR FLOW OF MATERIALS

SIZES

| Model | Tons | Yards³ | Model | Tons | Yards³ |

|---|---|---|---|---|---|

| HF0.25 | 0.25 | 0.18 | HF40 | 40 | 29.6 |

| HF1 | 1 | 0.7 | HF50 | 50 | 37 |

| HF2 | 2 | 1.5 | HF55 | 55 | 40.7 |

| HF5 | 5 | 3.7 | HF60 | 60 | 44.4 |

| HF10 | 10 | 7.4 | HF70 | 70 | 51.8 |

| HF20 | 20 | 14.8 | HF100 | 100 | 74 |

| HF25 | 25 | 18.5 | HF140 | 140 | 103.6 |

| HF30 | 30 | 22.2 | HF200 | 200 | 148 |

| HF35 | 35 | 25.9 | HF1000 | 1000 | 740 |

Complementary Equipment

Apron Feeders

Westpro’s mine-duty Apron Feeders are designed to thrive in the toughest mineral processing environments.

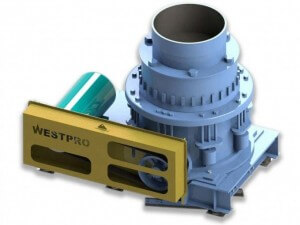

Cone Crushers

Westpro’s high productivity cone crushers are available as standalone units, modular assemblies, portable assemblies and as part of modular crushing plants

Jaw Crushers

Westpro’s heavy-duty jaw crushers are available as standalone units, modular assemblies, and portable assemblies and as part of modular crushing plants.

Portable Process Equipment

Westpro’s line of portable process equipment is ideal for use in aggregate quarries.