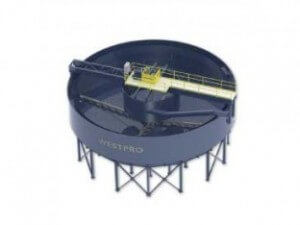

Thickeners

Westpro’s thickeners are equipped with new generation hydraulic drives, high capacity feedwells, and low drag-high capacity rakes to deliver superior solids settling performance. Along with their robust construction, Westpro’s thickeners ensure superior performance in high-torque applications.

ADVANTAGES

- Various tank construction options

- Low drag, high capacity rakes

- Specially engineered, high performance feed well designs for enhanced solids settling

- Options available for flocculant contactors and auto-dilution

- New generation hydraulic drive with high torque capability

- Integrated rake lift drive base with high capacity hydraulic cylinders

- Single hydraulic power unit powers both drive and rake lift

- Automatic rake lift system with pressure switch torque alarms

- Local control panel and PLC

- LOW MAINTENANCE

- RAKE PROTECTION SYSTEM

- EFFICIENT HYDRAULIC DRIVE

VARIOUS THICKENER DESIGNS

- High Capacity/High Rate

- Conventional

- High Density Underflow (HDU)

- Wastewater treatment

HIGH CAPACITY

- High capacity feedwell design with optimum retention time performance and even distribution of solids.

- High torque capacity rakes.

- Rake blades designed for precise removal of solids without disturbing the settled solids.

- Low maintenance hydraulic drive base with torque and rake position monitoring capabilities.

- Drive base lift up to 24″.

- Overflow turbidity and underflow density meter options available.

- Heavy duty bridge allowing for clear access to all drive components and process monitoring.

HIGH DENSITY UNDERFLOW

- High angle conical bottom offers high compression of underflow solids.

- Higher sidewalls than conventional thickeners allows for higher underflow SG densities.

- Feedwell evenly distributes the slurry throughout the tank allowing the solids to compress uniformly throughout the settling area.

- Feedwell is designed for optimizing flocculation time.

- High torque rake fitted with vertical pickets allows for water removal from the compacted sludge.

Click the gold circles below for an in-depth look at some of our key features!

Durable Feed Pipe

The Durable Feed Pipe utilizes flocculant injection ports to enhance solid settling performance.

Optional:

- Automatic Venturi for efficient dilution water mixing prior to the feedwell.

Energy-Dissipating Feedwell

Westpro's Energy-Dissipating Feedwell is optimized to ensure low-velocity, even slurry distribution - creating a stable, controlled environment that maximizes flocculant efficiency and promotes uniform settling.

High-Torque Compact Drive Unit

Westpro's Thickeners employ a High-Torque Compact Drive Unit to deliver reliable performance in high-density slurries. The system features active torque monitoring and automation with responsive rake lift and lowering for overload protection and process control.

Low-Drag, High-Capacity Rakes

A staple of Westpro's Thickeners are their Low-Drag, High-Capacity Rakes. Engineered to gently push settled solids toward the discharge point, these high-performance rakes minimize turbulence and preserve bed integrity for consistent underflow quality while ensuring consistent process flow.

Heavy-Duty Tank Design

Your choice of Welded or Bolted Tank Designs (depending on the Thickener size) are engineered and built to withstand harsh site climates and maintain structural integrity during prolonged, intense operation. These systems also come with customizable bridges, support structures, and access platforms tailored to your exact site layout.

Advanced Features

Optional:

- Advanced features include Bed Level Height Monitoring, Froth Suppression Baffles, and an Automated Spray Bar System to control froth buildup and maintain operational efficiency.

Integrated PLC and HMI System

All of Westpro's Thickeners come equipped with intuitive local control, real-time torque monitoring with automatic rake lift and bed engagement, alarm loggin, and seamless SCADA integration for full process visibility.

Monorail Structure

Optional:

- A Monorail Structure on the bridge (or below the understructure) are available for projects requiring additional lights or other accessories as part of their Thickener solution.

OPTIMIZED TO DELIVER SUPERIOR SOLID SETTLING PERFORMANCE THROUGH EXTENSIVE EXPERIENCE AND R&D

“Thickener runs like a charm!…”

Quebec

“Westpro’s thickener is one of the best pieces of equipment on our mine site…”

Newfoundland

“Westpro thickeners are robust and very low maintenance”

Mexico – Operating since 2002

Complementary Equipment

Clarifiers

Westpro’s Clarifiers have delivered proven wastewater treatment performance in both municipal and industrial applications.

Filter Presses

Westpro’s filter presses are suitable for applications in wide variety of industries and are fully customized to the requirements of each customer.

Flocculant Preparation & Dosing Systems

Westpro’s designs and manufactures turnkey modular Flocculant Preparation & Dosing Systems.

Pilot and Laboratory Equipment

In addition to its line of production machinery, Westpro manufactures a comprehensive range of pilot- and laboratory- scale equipment.