Agglomerators

Westpro’s agglomerators have delivered proven performance in crushed ore agglomeration globally for over 30 years. Built for the toughest operations, our agglomerators maintain Westpro’s signature robust construction while significantly improving heap leach recoveries in mining applications. Additionally, our agglomerators are customizable to meet the specific demands of each application.

ADVANTAGES

- Robust construction for tough mining environments

- Sizes ranging from 0.9m (3ft) diameter to 4.57m (15ft) diameter

- Up to 400HP (298kW) drives

- Rubber lining for wear and abrasion protection (other lining options available)

- Internal lifting bars on the drum, to gently tip the material and promote agglomeration

- Fully customizable with options such as additional spray bars, and fixed or adjustable drum angles

- Thanks to its design, it can be integrated into optional auxiliary equipment, such as exhaust gas cleaning systems

- Hardened steel tires, trunnion wheels and push rollers for equipment longevity and low maintenance

Download our brochure for more details including advantages and application.

APPLICATIONS

- Heap Leach Systems

- Pelletizing

- Granulation

PROVEN IN MINING HEAP LEACH OPERATIONS

CHAIN DRIVE AGGLOMERATORS

Westpro’s durable, high horsepower chain drive system is ideal for ore agglomeration. Our efficient chain drive agglomerators provide the most economical choice for Heavy duty applications.

ADVANTAGES

- Durable design

- High tonnage applications

- Long life cycle

- Low maintenance cost

Left: Two 3m (10ft) diameter chain drive Agglomerators at a gold heap operations in Mexico

| SIZES | (CHAIN DRIVE) | ||

|---|---|---|---|

| Model | Size (Diameter x Length) | Copper Leach (TPH) | Gold Leach (TPH) |

| AG310CD | 3′ x 10′ | 15-22 | 18-26 |

| AG416CD | 4′ x 16′ | 45-65 | 50-75 |

| AG518CD | 5′ x 18′ | 80-110 | 90-130 |

| AG622CD | 6′ x 22′ | 135-195 | 155-230 |

| AG724CD | 7′ x 24′ | 200-285 | 230-345 |

| AG830CD | 8′ x 30′ | 325-470 | 375-560 |

| AG930CD | 9′ x 30′ | 415-590 | 475-710 |

| AG1030CD | 10′ x 30′ | 510-730 | 585-875 |

| AG1140CD | 11′ x 40′ | 825-1180 | 940-1413 |

| AG1233CD | 12′ x 33′ | 810-1156 | 925-1390 |

| AG1240CD | 12′ x 40′ | 980-1400 | 1120-1680 |

TIRE DRIVE AGGLOMERATORS

Tire drive agglomerators eliminate the use of riding rings and use rubber tires. Tire drive agglomerators are engineered to ensure quality agglomeration of standard materials. Finite process control is available with the VFD package.

ADVANTAGES

- Eliminates riding rings and uses rubber tires

- Most economical

- Drum alignment is much less critical

- Suitable for most standard tonnage applications

- Short delivery time

Left: 2.4m (8ft) diameter tire drive Agglomerator at the Westpro shop in Ontario, Canada

| SIZES | (TIRE DRIVE) | ||

|---|---|---|---|

| Model | Size (Diameter x Length | Copper Leach (TPH) | Gold Leach (TPH) |

| AG612TD | 6′ x 12′ | 60-80 | 70-100 |

| AG816TD | 8′ x 16′ | 140-190 | 160-240 |

| AG830TD | 8′ x 30′ | 260-375 | 300-450 |

| AG930TD | 9′ x 30′ | 331-470 | 380-570 |

| AG1030TD | 10′ x 30′ | 410-585 | 470-700 |

| AG1233TD | 12′ x 33′ | 650-925 | 740-1110 |

GEAR DRIVE AGGLOMERATORS

| SIZES | (GEAR DRIVE) | ||

|---|---|---|---|

| Model | Size (Diameter x Length) | Copper Leach (TPH) | Gold Leach (TPH) |

| AG1340 | 13′ x 40′ | 920-1315 | 1050-1580 |

| AG1550 | 15′ x 50′ | 1530-2190 | 1750–2630 |

Complementary Equipment

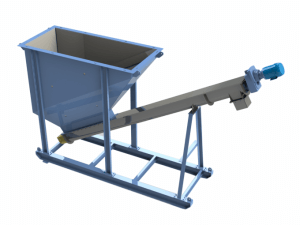

Hopper Feeders

Available as stationary, modular and portable units, Westpro’s heavy-duty Hopper Feeders are suitable for any scale mining or aggregate project.

Jaw Crushers

Westpro’s heavy-duty jaw crushers are available as standalone units, modular assemblies, and portable assemblies and as part of modular crushing plants.

Portable Crushers

Westpro’s portable jaw and cone crusher units deliver self-contained crushing solutions for quarries, remote sites and construction projects.